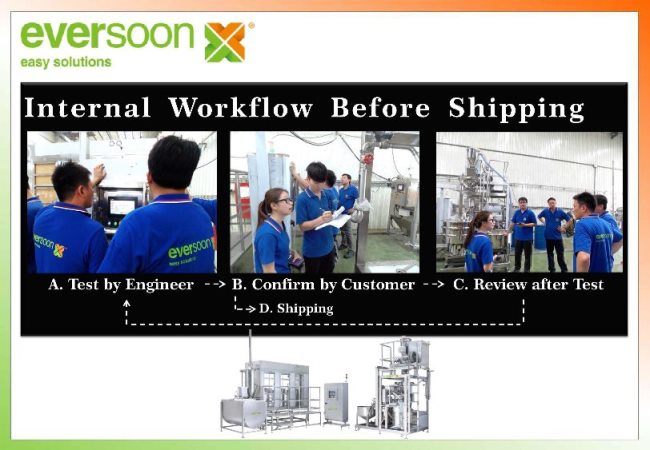

Internal Workflow before Shipping

We have a complete delivery process when tofu and soy milk production line is completed. Following have four steps before shipping:

A. Test by Engineer

Every completed tofu and soy milk production line will be test in our factory. This step will check the software and hardware by the engineers. After test and adjust, then invite the customer to Taiwan for testing.

B. Confirm by Customer

There are two ways of completed tofu and soy milk production line testing. First, some customers will come to Taiwan to attend the test. And offer feedback to our engineers and sales immediately. After communication between customers and engineers, we will arrange technician to removal problem of machine and optimization. Second, some customers didn’t come to Taiwan to attend the test. We will record the video when completed production line testing. And provide the movie to check by the customer.

C. Review after Test

After the test, we will hold a meeting immediately. According to feedback from customers and engineer instruction to assign the technician to each worklist. At the same time, select the date and time to go to the second test.

D. Shipping

After step B, then customers have no common, the process will enter to loading and shipping. Or after the modification of step C, and then return to step B, and testing get the satisfied reply by customers. The process will enter to loading and shipping also.

To complete the above steps of tofu and soy milk production line. We will arrange engineers and sales to go to install production line. And re-test after complete assembly to ensure the customers can use our equipment to produce a satisfied product. In addition, the engineer and sales will also assist the education training, the project includes:

1. Machine operation and program setting.

2. Quality management.

3. The way of equipment maintenance and periodic replacement of components.

4. Instructions of tofu or soy milk production line.

In these process and steps, you will find that EVERSOON is not only a company of selling food machinery. We also provide a variety of equipment testing and employee training to help customer to produce tofu and soy milk faster. Most of all, the finished products need to satisfy the needs of the market.

Internal Workflow before Shipping | CE Certified Tofu Product Line, Soybean Soak & Wash Tank, Grinding & Cooking Machine Manufacturer | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a food manufacturing machine manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

Yung Soon Lih has more than 30 years of food machinery manufacturing and technical experience, professional production: Tofu Machine, Soy Milk Machine, Alfalfa Sprouts Germination Equipment, Grinding Machine, etc.