Grinding and Okara Separating and Cooking Machine

Automatic Soybean Grinding and Okara Separating and Cooking Machine

Grinding, separating and cooking equipment play an important role in the production process of soy milk and tofu. They are not only closely related to the production capacity of soy milk and tofu, but also have significant implications for production efficiency. Applicable products: Various types of beans such as soybeans. It can be used to produce vegetarian protein food production, Regular Tofu (Firm Tofu), Silken Tofu (Soft Tofu), Fried Tofu, Vegetable Tofu (Tofu with Vegetable and Herbs), Tofu Burger (Tofu Patty), Tofu Sausage, Vegetarian Meat, Tofu Skin, Egg Tofu, Japanese Tofu, soy milk (Long Life soy milk).

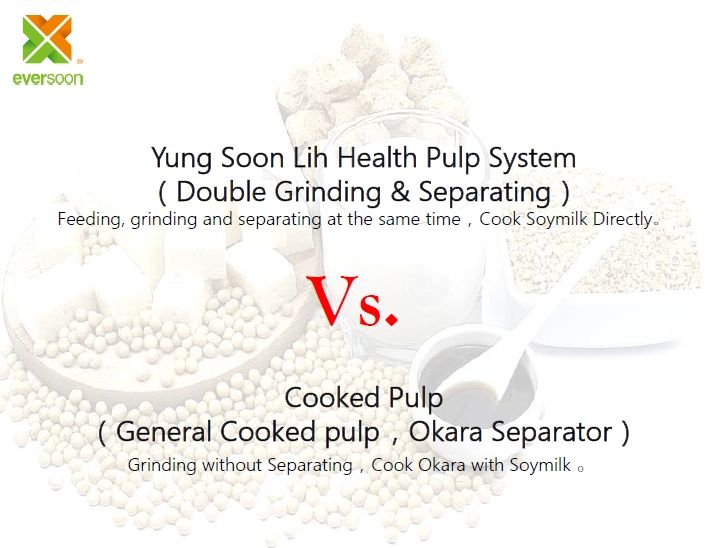

The Difference Between Health Pulp System and Cooked Pulp System

In the production equipment for soy milk and tofu, there are two main systems: the Health Pulp System and the Cooked Pulp System. In order to meet the diverse capacity needs of different customers, Yung Soon Lih provides tofu and soy milk manufacturing equipment with the health pulp system based on different capacity. They have different operation methods, below are detailed information:

*Health Pulp System of Tofu & soy milk Production Line

The process of feeding, grinding, and separating is completed in one step, and immediately transferred to cooking machine for heating directly. That’s say, the Health Pulp System heats the soy milk directly. It eliminates the energy consumption required for heating the soy pulp separately. When soy milk enters the next step, it also doesn't need to be heated again, resulting in reduced energy consumption and lower production costs.

Additionally, the concentration of the soy milk can be monitored before entering the heating process, allowing for immediate adjustment of the water input during the grinding operation. This ensures more accurate monitoring of soy milk concentration and makes quality control easier.

Associated Equipment:

• Grinding & Okara Separating & Cooking Machine• Grinding & Okara Separating Machine

• TWIN GRINDING & OKARA SEPARATING & COOKING MACHINE

• Twin_grinding_separating_machine

• F1404 Grinding & Separating Machine

(※ Please follow the link below for more product information and specifications)

* Cooked Pulp System of Tofu & soy milk Product Line:

After feeding and grinding of Soybean, soy milk and Okara enter into a cooking machine together. This design requires heating both the soy milk and Okara together, and after the heating process is complete, the separating operation is carried out.

The Difference Between Health Pulp System and Cooked Pulp System

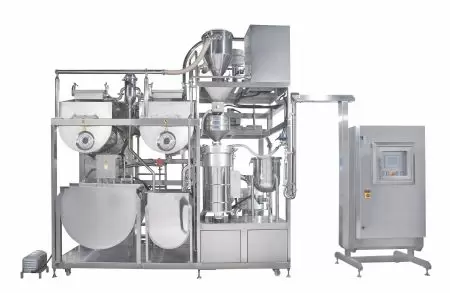

According to different grinding methods, Our Grinding And Okara Separating And Cooking Machine is divided into grinding and twin-grinding. Customers can make the most suitable choice according to product capabilities and needs.

Grinding: General grinding machine in the market only extraction soymilk in one time, then separating okara and throw the okara. But there have a lot of nutrients in soybean okara, like protein and soy isoflavones etc.

Associated Equipment:

• Grinding & Okara Separating & Cooking Machine• Grinding & Okara Separating Machine

Twin-Grinding: It could increase soy protein extraction from same material quantity and having stable concentration of milk for making Tofu. At the same time, discharge the bean okara is lower water content, also easier recycle and transfer.

Associated Equipment:

• TWIN GRINDING & OKARA SEPARATING & COOKING MACHINE• Twin_grinding_separating_machine

•F1404 Grinding & Separating Machine

(※ Please follow the link below for more product information and specifications)

Single/Double Grinding & Deslagging Pulp Cooking Equipment

Single Grinding & Deslagging Machine provides different capacity requirements, the capacity...

Details Add to ListSingle/Double Grinding & Deslagging Equipment

Single grinding & Deslagging Machine provides different capacity requirements, the capacity...

Details Add to ListDouble Line Double Grinding Deslagging Equipment

Double line double grinding and dregs removal system has four grinding and dregs removal machines,...

Details Add to ListGrinding and Okara Separating and Cooking Machine - Automatic Soybean Grinding and Okara Separating and Cooking Machine | Professional Soybean Processing Equipment Supplier For 32 Years in Taiwan | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a Grinding and Okara Separating and Cooking Machine manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

EVERSOON, a brand of Yung Soon Lih Food Machine Co., Ltd., is a leader of Soy Milk and Tofu Machines. Being a guardian of food safety, we share our core technology and professional experience of Tofu production to our worldwide customers. Let us be your important and powerful partner to witness your business growth and success.