Double Line Double Grinding Deslagging Equipment

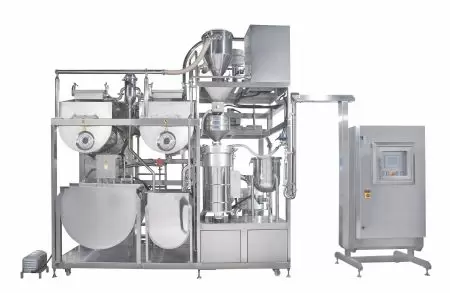

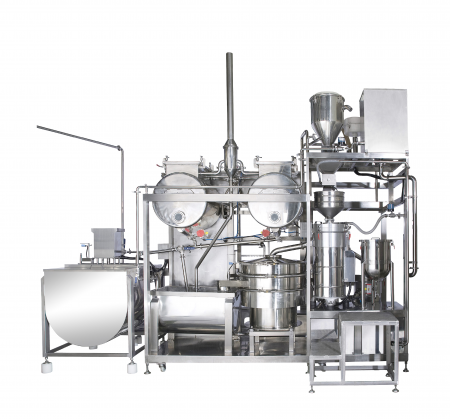

Double Line Double Grinding Deslagging Machine

Double line double grinding and dregs removal system has four grinding and dregs removal machines, the capacity of this equipment can be up to 400~440kg/hr.

【Yung Soon Lih Double Line Double Grinding Deslagging Equipment】

Fully automatic dual-line double grinding bean deslagging system equipment, is the food machinery equipment designed by Yung Soon Lih for the demand of large capacity customers, in addition to increasing the soybean, soybean milk protein extraction rate of nearly 5% also enhance the production capacity. In addition to the advantages of fully-automated machinery to stabilize the quality of the products and save labor costs, Yung Soon Lih equipment uses human-machine system (HMI interface) and computer control system (PLC interface) to adjust the operation of the machine and control the production process, so as to make the output stable and greatly reduce the uncertainty of the output.

Double Line Double Grinding Deslagging Machine(F1404)Combining the human-machine system with the computer control system, the machine operation mode and production output can be adjusted with simple operations on the panel, providing the advantage of flexible production line planning. Customers can adjust product output at any time according to production needs.

F1404Fully automatic standardized production equipment reduces labor costs and product depreciation rates. In terms of management, the reduction in operators reduces the management burden on managers, allowing managers to use their time more efficiently on other operations.

【Feature of Yung Soon Lih Double Line Double Grinding Deslagging】

The CIP cleaning system saves manpower, energy consumption, and cleaning costs, and can also allow equipment buyers to significantly shorten the equipment cost recovery period. Generally, other factories' grinders separate and discard the dregs after one grinding; however, the moisture content and residual protein of the dregs are still high, resulting in waste of raw materials and costs. By using Yongshunli soybean dregs separation equipment, the discharged dregs have low moisture content and are easier to recycle and transport. The advantage of our equipment is that it reduces the waste of raw materials, saves manpower, increases product output and also increases the additional income of the equipment.

Features

- The double line double grinding and deslaging system is designed with four bean grinders and deslaging machines, which increases the protein extraction rate of raw materials by about 5%, which is equivalent to a 5% increase in production capacity.

- Human Machine Interface the system can adjust equipment operation in real time and automate the entire machine operation, thus improving product control quality at the lowest management cost. In addition, the machine operation design adopts dual-mode control of human-machine interface and mechanical buttons, and the program parameter settings are quickly adjusted and the operation is easy.

- High-efficiency grinding and dregs removal system, high soy milk protein extraction rate, low moisture content of dregs, easy recycling and transportation, reducing waste residue treatment costs, increasing output value and reducing costs.

- Multi-machine integration and CIP (Clean In Place) raw pulp barrel cleaning system design; compared with each independent machine, the unit occupies a smaller space, the high protein extraction rate increases the production capacity, the panel operation is simple, the CIP design makes it easy to disassemble and assemble the equipment pipeline, saves cleaning costs (water costs, labor expenditure costs) and achieves rapid cleaning.

- F1404 made of 304 stainless steel and equipped with CIP raw pulp barrel tank cleaning system, the machine has high durability and improved cleaning and maintenance capabilities.

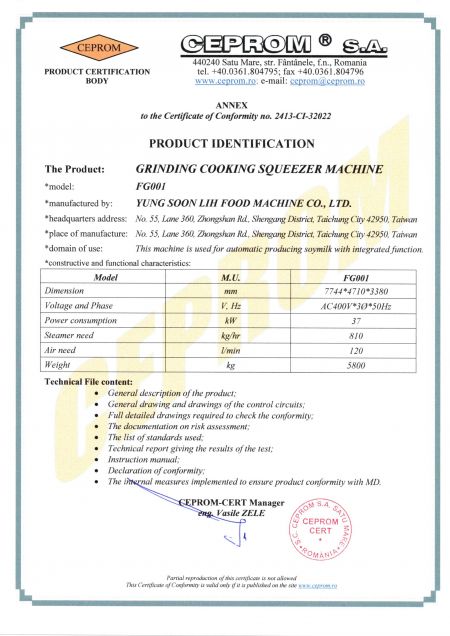

F1602TA(F16 two units with cooking equipment)

60HZ Capacity:65 ~ 75 kg/hr

50HZ Capacity:50 ~ 60 kg/hr

F1502TA(F15 two units with cooking equipment)

60HZ Capacity:130 ~ 150 kg/hr

50HZ Capacity:100 ~ 125 kg/hr

Above grinding concentration is set at 12.5 degrees

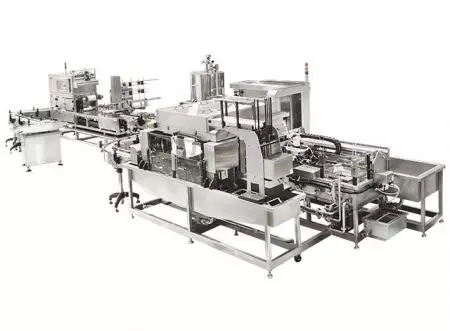

Tofu production equipment production steps flow chart

Double Line Double Grinding Deslagging Machine(F1404)It belongs to the front-end equipment of the tofu production line. After the soybeans are washed and soaked, the soybeans are transported from the bean washing and soaking tank to the bean grinding and de-slaging machine through the vacuum conveyor above the bean grinding and de-slaging machine. The raw pulp after grinding and de-slaging is stored in the raw pulp barrel for subsequent operations. F1404 is located at step 4 in the entire tofu and soy milk production line. Please see the figure below for details.

Applications

Application of Double Line Double Grinding Deslagging Equipment

Soybean, black bean and other kinds of soybean grinding, deslagging, cooking operation, can be used to produce firm tofu, silken tofu, fried tofu, vegetable tofu, soymilk, dried bean curd, and Douhua.

Services

Yung Soon Lih (eversoon) Food Machine provides 24-hours online consultation, cooperates with engineers to solve customers’ problems by remote operation, saves people's round-trip time and labor cost, and solves customer problems in a timely and rapid manner.

In addition, food equipment who just started their business or expanded their factories, our senior engineers will go to the company site to survey and help you to plan the layout. In the past 36 years, We had built up a good partnership with our global customers like the Czech Republic, Poland, Canada and also transferred the technical know-how of producing soy milk and tofu to our customers. We were committed to becoming a turnkey solution provider.

- MoviesProduct PatentsRelated ProductsFiles Download

Double Line Double Grinding Deslagging Equipment - Double Line Double Grinding Deslagging Machine | Taiwan-Based Soybean Processing Equipment Manufacturer Since 1989 | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a Double Line Double Grinding Deslagging Equipment manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

We are the first food machine manufacturer whom developed the European Tofu turn-key production line, which can produce Asian Tofu, and Soy Milk processing equipment. Our tofu production machines are specially design and able to produce Tofu Burger, Vegetable Tofu, Smoked Tofu, Tofu Sausage to satisfy consumers' demand from the American and European market.