Tofu Production Line

Firm Tofu and Silken Tofu Making Equipment

With the ESG United Nations Global Compact (UN Global Compact) first proposed the concept of ESG in 2004, it is regarded as an indicator for evaluating a company's operations. Advocate the sustainable development of enterprises as the premise, and the concept of caring for the earth is a constant topic.

If you want to invest in the food industry and meet the environmental protection, love the ball and protect animals, it is the tofu production line. Tofu is a plant-based protein source that the human body needs, is a very common food on the table of Asians(also known as water tofu). Tofu not only has a high content of protein, but also has a solid taste and a full body after eating. The feeling of fullness attracts many women who want to lose weight and maintain their figure. Tofu can be designed in a variety of dishes, making tofu a new favorite among vegetarian and healthy dishes.

Tofu is not originally in the Asian market, consumers in European and American countries are more inclined to those foods that have high demands on health and also care about energy-saving and carbon-saving lifestyles.

There is a trend in the demand for tofu dishes.

Mainly the following factors:

1. During the cultivation of animal protein, a large amount of methane will be emitted to destroy the ozone layer, under the awareness of environmental protection, plant protein has become a new choice.

2. Animal protein is an important source of nutrition during the growth process, however, during the intake process, too much fat is also eaten, which increases the burden on the body and cardiovascular diseases.

Therefore, the trend of replacing animal protein with vegetable protein is gradually formed. In terms of specific market changes, for example, European and American countries add an appropriate amount of tofu to sausages and hamburger steaks (replacing some beef or pork), and even traces of tofu can be seen in chicken nuggets and pasta sauce.

3. The rise of vegans, the consumer population who became vegetarian due to various factors is increasing rapidly, and in the alternative meat market, soybeans and barley are mainly used as raw materials to make other foods. The tofu made from soybeans is very plastic, and many restaurants in Europe and the United States have developed more dishes and are deeply loved by consumers. For example, tofu burger, vegetable tofu, tofu sausage.

Under the influence of many factors, the tofu and soybean milk market is growing at a rate of 15-20% per year. Facing such a fast-growing and huge tofu market, the traditional way of making tofu with a single machine can no longer satisfy the market.

Therefore, from 1990 to 2000, we began to integrate the stand-alone equipment developed within the company, and actively invested in the planning of tofu production line and the manufacture of tofu production line equipment. In 2023, we will actively develop distribution partners for the joint operation of tofu production, and assist in the construction of large-scale tofu production lines in food processing plants in Germany, France, Canada, the United States to increase production capacity, and to improve the problem of manpower shortage with automated systems.

The rapid profit is far beyond your imagination, because it has been proved that our customers, after a year from a production line, must add a second repair line.

Specifications

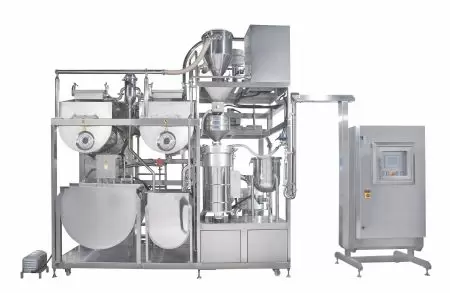

- Washing and Soaking Machine: Computer parameters can be set the soaking time, drainage time, temperature sensor and water changing time.

- Grinding Machine: Computer parameters can be set the amount of soybeans, water volume, stable soy milk concentration. The hopper which was designed with the gold cone angle can used to increase the extraction rate of soybean protein. It can be increased the extraction rate of soybean protein by about 5% when using secondary grinder.

- Cooking Machine: Computer parameters can be set the sucking time, injecting time, cooking time.

- Coagulation Machine: Computer parameters can be set tofu coagulation injection time and dose, grouting and slurry discharge time.

- Pasteurization Machine: Computer parameters can be set individual tank temperature,conveyor belt speed time.

Through this period, we got satisfied reviews from our customers, like low breakdown rate, high durability, high capacity with efficiency, quick response and high quality after service.

More importantly, our customers got 15 ~ 20% growth rate every year from Yung Soon Lih Tofu Processing Equipment. Also, our customers save 20~30% in maintenance cost compared with our competitors.

We dare to say proudly, that the first Tofu Production Line made from YUNG SOON LIH FOOD MACHINE is still working as usual every day, and has undergone several expansions of production capacity. This is the result of our commitment to manufacturing good quality products and offering dedicated customer services.

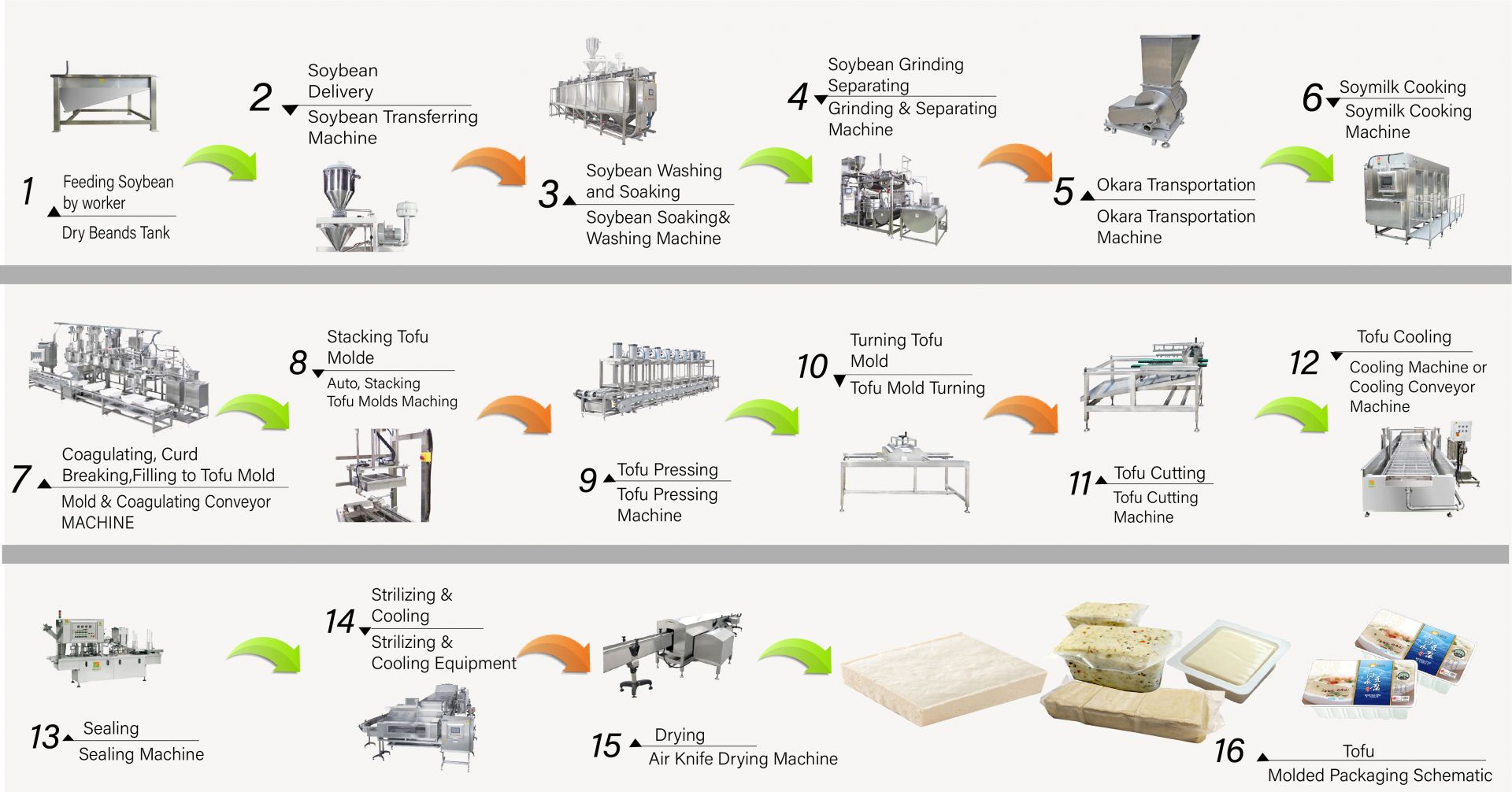

Process of Tofu Production Line

Firm Tofu & Silken Tofu Production Line operating process flow chart for your reference.

Step Process

1. Feeding Soybean to Dry Beans Tank by worker.

2. Transferring Soybean from Dry Beans Tank to Soybean Soaking & Washing Machine by Soybean Transferring Machine.

3. Soybean Washing and Soaking.

4. Soybean grinding and separating in Automatic Soybean Grinding & Okara Separating Machine (or Automatic Soybean Twin Grinding & Okara Separating Machine).

5. Delivering Soybean okara by Okara Transportation Machine.

6. We offer two type of soy milk cooking machine for our customer to choose, one is General Automatic soy milk Cooking Machine, the other is CE soy milk Cooking Machine.

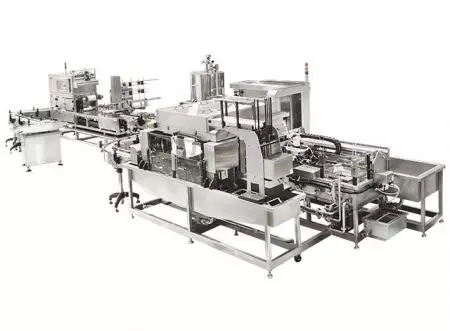

7. Coagulating and Curd Breaking by Tofu Coagulating Machine and using conveyor machine to deliver Tofu coagulating bottles to Tofu Filling to Mold Machine.

8. Before Tofu Pressing, using Auto Stacking Tofu Molds Machine to stack Tofu Molds, and delivering Tofu Molds to Tofu Pressing Machine.

9. Tofu Pressing by Tofu Pressing Machine, it's easily time saving and efficiency increasing.

10. Removing Tofu Mold and Tofu clothing by Tofu Mold Turning Machine.

11. Tofu Cutting Machine assisting you to cutting easier and saving time.

12. Before packaging and sealing step, we suggest adopting Cooling Machine reducing temperature of Tofu surface and inside.

13. Putting Tofu into Tofu Box by manual and using Sealing Machine doing package process.

14. Putting Tofu into Sterilizing & Cooling Equipment for sterilization to extend expiry date.

15. Drying box of Tofu by Air Knife Drying Machine.

16. Putting into refrigerator for storage.

Applications

What is the sociability of Yung Soon Lih (eversoon) tofu making machine?

Different kinds of tofu have different texture, firmness and different meal application on your table, Yung Soon Lih (eversoon) tofu making machine is able to sociable with optional device to produce extra firm tofu, and Asian silken tofu.

I want to learn use of Extra Firm Tofu & Herb Mixed Tofu?

Extra Firm Tofu, and Herb Mixed Tofu, these 2 kinds of tofu are facing to Western people market main stream market in United States, Europe because they are firmer, the taste is quite similar to animal meat, so it is very suitable for BBQ, putting extra firm tofu small cubes on to the pizza, and also small cubes into salad.

Service

Yung Soon Lih (eversoon) Food Machine provides 24-hours online consultation, cooperates with engineers to solve customers’ problems by remote operation, saves people's round-trip time and labor cost, and solves customer problems in a timely and rapid manner.

In addition, food equipment who just started their business or expanded their factories, our senior engineers will go to the company site to survey and help you to plan the layout. In the past 36 years, We had built up a good partnership with our global customers like the Czech Republic, Poland, Canada and also transferred the technical know-how of producing soy milk and tofu to our customers. We were committed to becoming a turnkey solution provider.

- MoviesRelated ProductsFiles Download

In Tofu Production Process video clip, you can easily understand how the tofu maker machine makes the Tofu. Including the process of Soybean feeding, grinding, okara separating, raw Soy milk making, Soy milk cooking, pumping to coagulation tank, stirring, tofu pressing and filling to molds.

In Tofu Production Process video clip, you can easily understand how the tofu maker machine makes the Tofu. Including the process of Soybean feeding, grinding, okara separating, raw Soy milk making, Soy milk cooking, pumping to coagulation tank, stirring, tofu pressing and filling to molds.

Suction Equipment

In the Tofu and Soy Milk Production Line, the soybeans suction equipment not only saves labor...

Soaking & Washing Machine

The quality of Soybean Soaking & Washing Machine is the key for making Tofu and soy milk!

Grinding & Separating Equipment

Grinding, deslagging, filtering and cooking equipment is an important role in the production...

Squeezer Equipment

Production of tofu, soymilk process, generally is grinding beans, cooking and then enter the squeeze...

Okara Transportation

After grinding the Soybeans, use the Okara Transportation Machine to discharge Okara.

Automatic Soymilk Cooking Equipment

Yung Soon Lih Food Machinery's cooking equipment is equipped with automatic temperature and pressure...

Coagulation Equipment

The automatic coagulating machine can reduce manpower and improve the efficiency of the tofu...

Auto Stacking Tofu Mold Machine

Use a mechanical arm to deliver Tofu molds to the continuous pressing machine. This could decrease...

Tofu Press Equipment

With the ability to estimate the expected yield according to the molding time, this equipment...

Mold Turning Machine

Following the pressing and removing of the upper part of the mold, the Tofu mold turning machine...

Cutting Equipment

In the early days, manual cutting of tofu would lead to uneven cutting size, easy breakage...

Cooling Machine

Tofu are cut at a high temperature, and need to be cooled down in low-temperature places before...

Tofu Production Line - Firm Tofu and Silken Tofu Making Equipment | Professional Soybean Processing Equipment Supplier For 32 Years in Taiwan | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a Tofu Production Line manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

EVERSOON, a brand of Yung Soon Lih Food Machine Co., Ltd., is a leader of Soy Milk and Tofu Machines. Being a guardian of food safety, we share our core technology and professional experience of Tofu production to our worldwide customers. Let us be your important and powerful partner to witness your business growth and success.