What do you think is the most important factor causing labor shortage in tofu factories nowadays?

Poor working environment: The working environment in tofu factories is often humid and stuffy, and requires long hours of standing work, which makes the work more intense.

1. Humid and stuffy: Tofu factories require a lot of water in the production process, so the air humidity is relatively high. In addition, the production equipment in tofu factories tends to generate a lot of heat, which leads to a high temperature in the working environment.

2. High work intensity: The production process in tofu factories is cumbersome and requires a lot of manual labor. In addition, the production lines in tofu factories are often continuous, so workers need to stand for long periods of time.

3. Possible safety hazards: Tofu factories need to operate equipment during the production process, such as mixing and breaking tofu/tofu presses by machine and so on, which are dangerous for workers' safety.

The following is a suggestion for improvement:

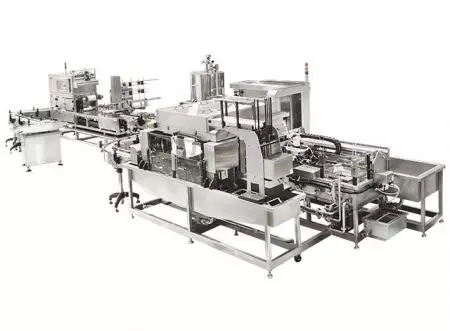

>Tofu factories can introduce automated production equipment to reduce the workload of employees, firstly, to improve the cleanliness of the environment, secondly, to improve the shortage of manpower, thirdly, to stabilize the quality of tofu products.

Hot articles

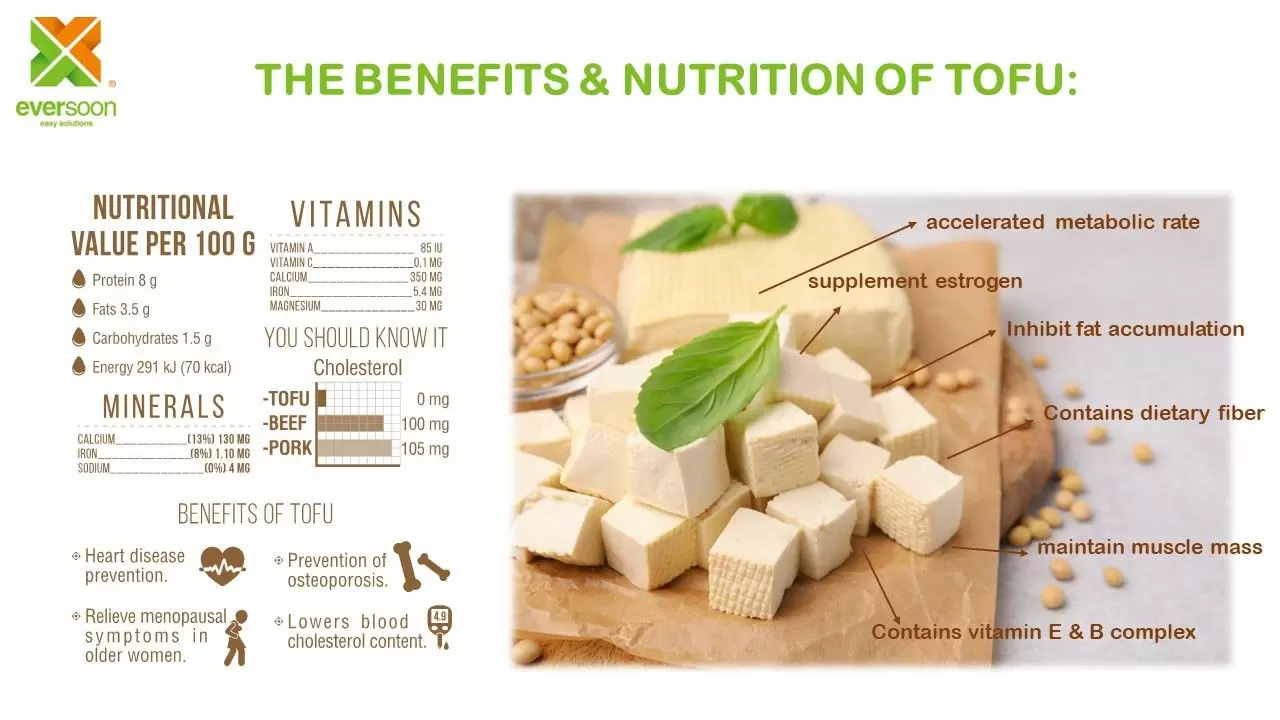

2020-2024 Health benefits of tofu will increase market demand

When is the best time to drink soy milk?

Benefits And Nutrition Of Tofu

Canada Food Guide Changes: More Veg, Less Meat, And No More Eating Alone

- Related Products

Automatic Tofu Cutting Equipment

Tofu Automatic Cutting Machine adopts three sections to detect the whole slab of tofu which is automatically introduced, the first section detects and cuts...

Details Add to cartAutomatic Cutting Equipment for Tofu in Water

After the operator pushes the unmolded tofu plate into the automatic cutting machine in tofu water, the machine is equipped with a conveyor belt that automatically...

Details Add to cartTofu Manual Cutting Equipment

In the early days, tofu manufacturers or tofu workshops used to cut tofu with a kitchen knife, which not only tested the master's knife skills over the years,...

Details Add to cartContinuous Tofu Pressing Machine

After the tofu molds are stacked and transported to the tofu press station, the conveyor belt of the tofu press is synchronized and the tofu molds are automatically...

Details Add to cartTofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The machine is manually operated, it is using the principle of lever to reduce the weight...

Details Add to cartsemi Auto.Tofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The operator pushes the tofu mold into the tofu mold turning box to the end, presses...

Details Add to cart

What do you think is the most important factor causing labor shortage in tofu factories nowadays? | CE Certified Tofu Product Line, Soybean Soak & Wash Tank, Grinding & Cooking Machine Manufacturer | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a food manufacturing machine manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

Yung Soon Lih has more than 30 years of food machinery manufacturing and technical experience, professional production: Tofu Machine, Soy Milk Machine, Alfalfa Sprouts Germination Equipment, Grinding Machine, etc.