120kg/hr Dry Soybean Processing: Automatic Tofu Making Machine Solution

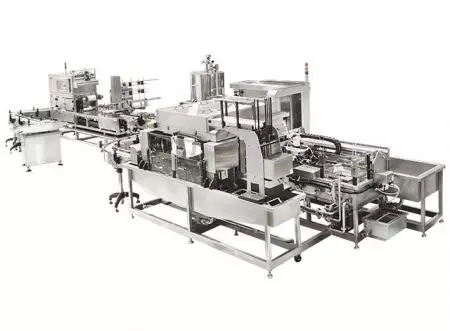

Yung Soon Lih (eversoon) Food Machine is a state-of-the-art tofu production line. This advanced system boasts an integrated soymilk extraction unit, offering a dry bean processing capacity ranging from 100 to 120 kilograms per hour. This highly efficient tofu production line, designed in line with Yung Soon Lih (eversoon) Food Machine Company renowned coagulators, is capable of churning out 30 to 35 molds of natural standard tofu or 20 to 25 molds of firm tofu per hour, each mold weighing approximately 8.7 kilograms.

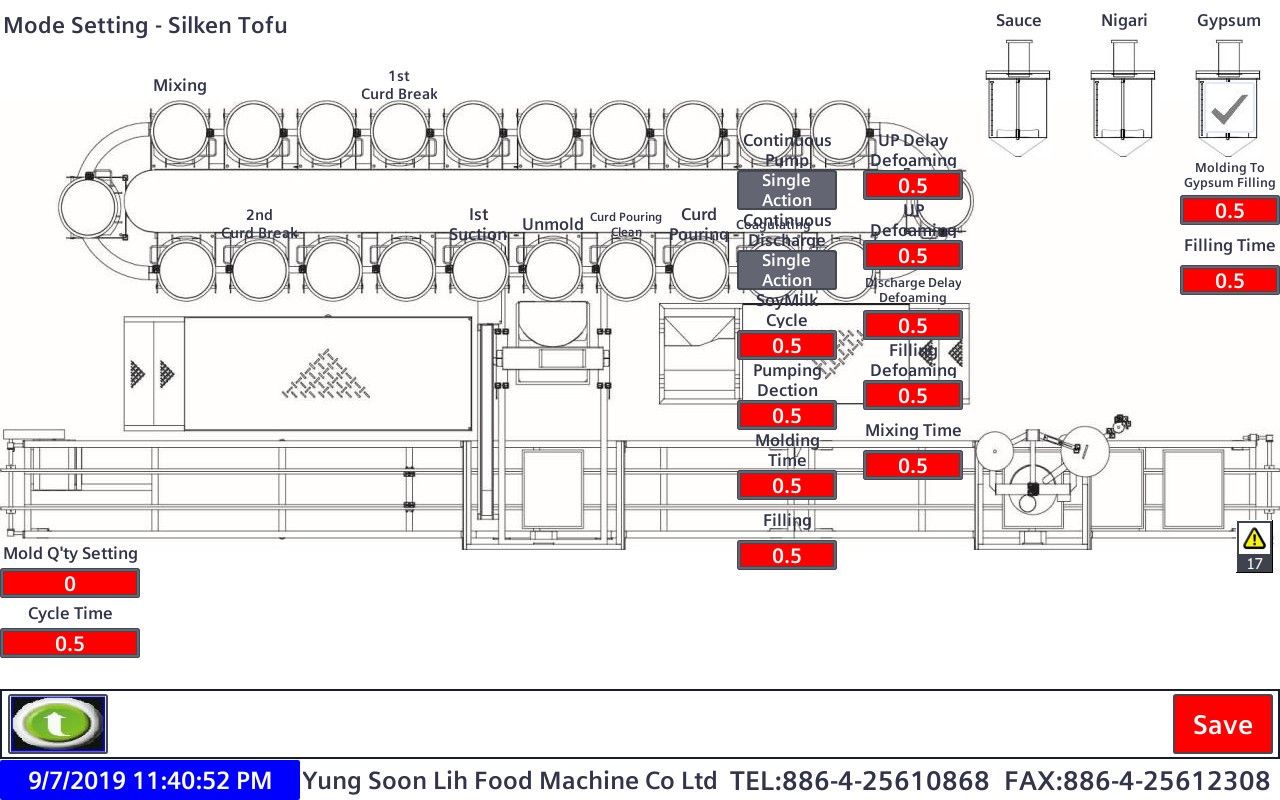

Yung Soon Lih (eversoon) Food Machine dry soybean processing offers a cutting-edge tofu production solution with a processing capacity of 120 kilograms per hour. This automated system leverages smart technology to meticulously oversee every aspect and parameter of the tofu-making process, guaranteeing consistent and exceptional quality at all times. Crafting tofu is as easy as a single click on the user-friendly HMI interface, and with just three days of training, you can become proficient in producing top-tier tofu.

Effortless Operation – No Specialized Training Required

The Yung Soon Lih (eversoon) Food Machine tofu production line is designed for simplicity, requiring no specialized or extensively trained workforce to operate. Workers can efficiently perform straightforward tasks such as placing tofu molds on a conveyor belt and organizing tofu curds. This intuitive design reduces labor costs and accelerates onboarding for new employees.

Intuitive Interface – As Easy as Using a Tablet

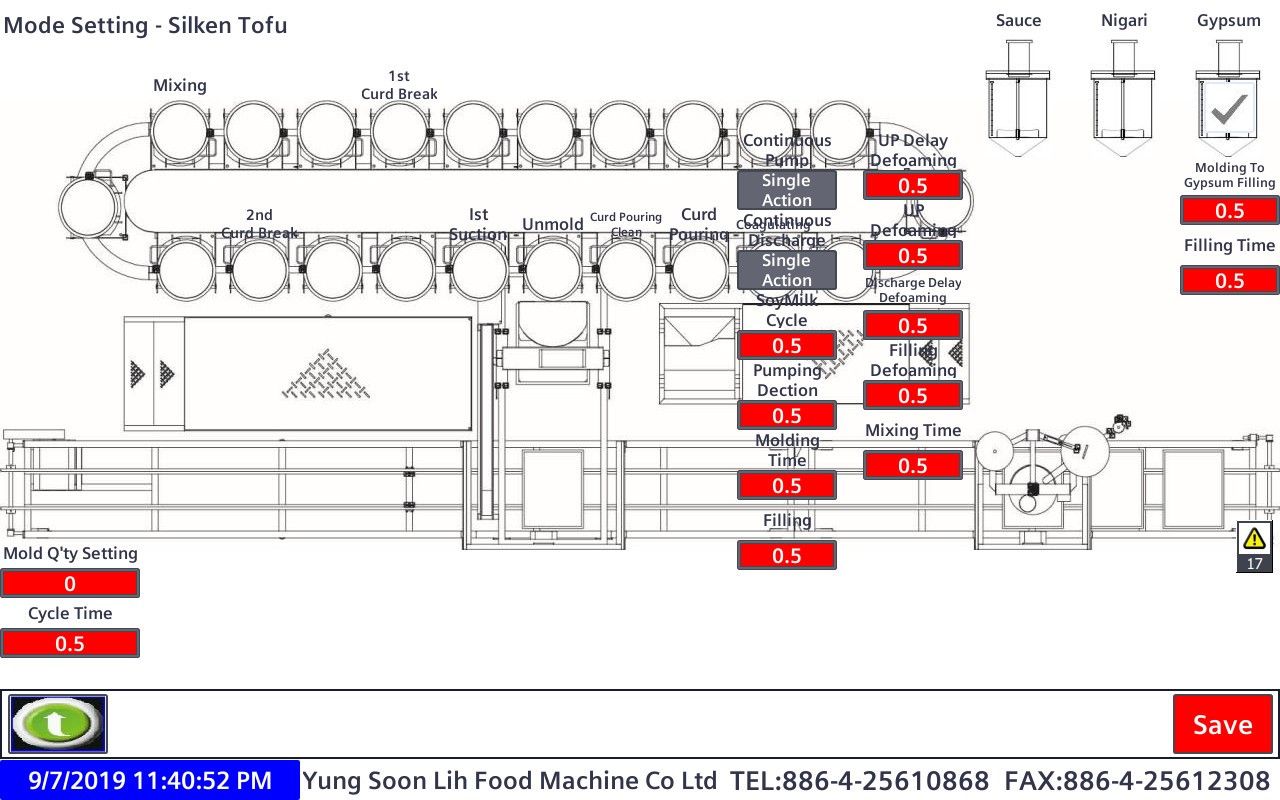

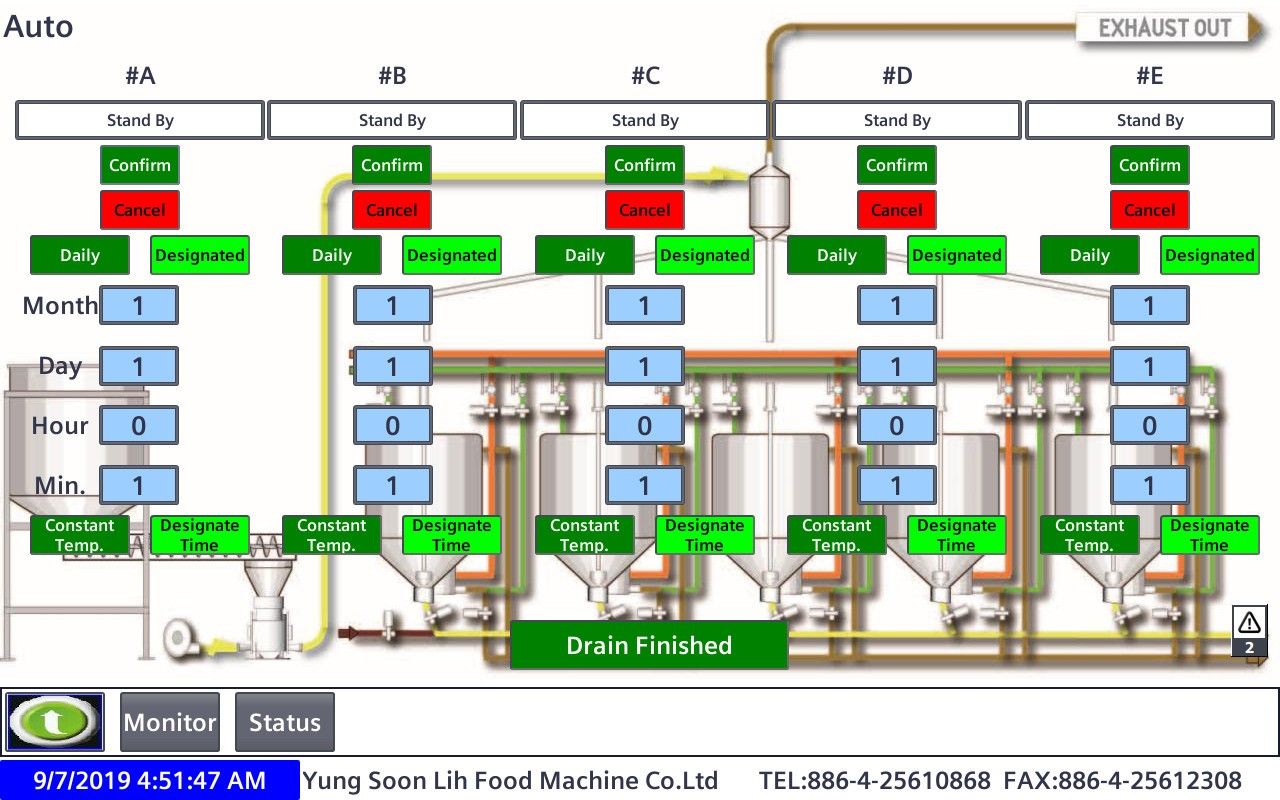

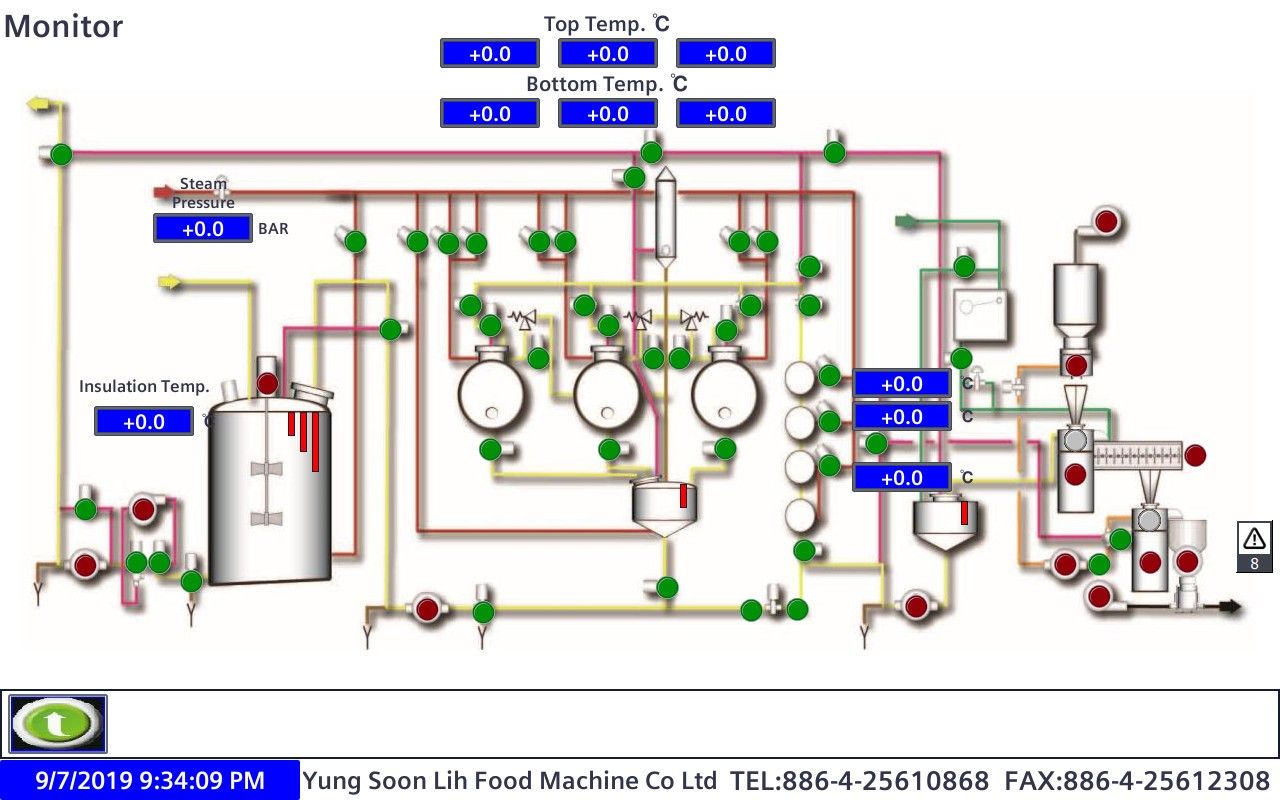

The system features a user-friendly HMI (Human-Machine Interface) and PLC (Programmable Logic Controller), making operation as simple as using a tablet. The intuitive interface allows workers to quickly learn and manage the process, ensuring smooth production with minimal supervision.

Remote Monitoring and Troubleshooting

With PLC and HMI integration, Yung Soon Lih (eversoon) Food Machine engineers in Taiwan can remotely monitor the system, conduct health checks, and troubleshoot issues via remote access connections. Additionally, if the HMI encounters issues, a regular laptop can replace it, ensuring uninterrupted production.

Hassle-Free Maintenance and Easy Cleaning

Designed with efficiency in mind, the tofu production line includes an easy-to-clean system, featuring self-cleaning pipes, buffer tanks, and steaming tanks. Coagulation tanks can be soaked in Alkali water, simplifying the cleaning process and maintaining hygiene standards effortlessly.

A Smart Choice for Tofu Production

Yung Soon Lih (eversoon) Food Machine tofu production line is a user-friendly, low-maintenance, and highly efficient solution. With its remote control access, intuitive interface, and simplified operation, tofu production has never been easier—just a single click to start!

The Perfect Partner for Tofu Production

If you're new to tofu production and looking to enter the industry, Yung Soon Lih (eversoon) Food Machine is your ideal partner. We provide not just machinery but also technology transfer and a full range of tofu production equipment, ensuring a smooth start to your business.

Eliminate Trial and Error – Save Time and Resources

Traditional tofu-making involves years of trial and error, consuming valuable time and resources. By choosing Yung Soon Lih (eversoon) Food Machine, you can bypass the lengthy learning curve and immediately begin producing high-quality tofu with precision and consistency.

Gain a Competitive Edge and Ensure Success

Partnering with us allows you to enter the tofu industry quickly and efficiently, giving you a competitive advantage. Our advanced technology ensures high production efficiency, quality consistency, and maximum return on investment, making your tofu business a profitable and sustainable venture. Start your tofu production journey today with Yung Soon Lih (eversoon) Food Machine—your trusted partner for success!

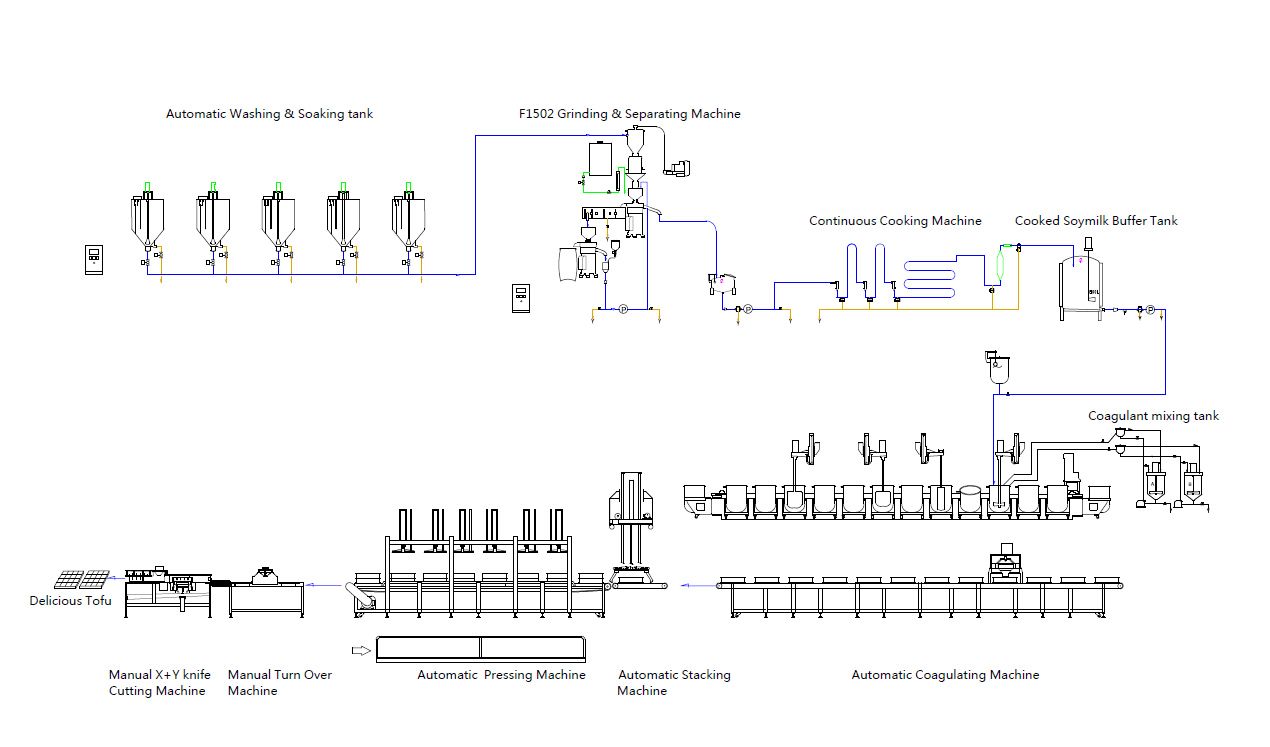

l Tofu Production Process Flow: (P&ID) l

l Machine Lists l

Product Name | Specification |

1. Automatic Washing & Soaking Tanks | <Volume 240kg*5 tanks> |

2. Automatic Soybean Grinding & Separating Machine | <F1502> |

3. Continuous Cooking System (with anti-deformer agent) | <Capacity: 1000L/HR> |

4. Buffer Tank (included sanitary pump) | <Volume:1,500L> |

5. Self Circulation Cleanness System |

|

6. Tofu Coagu-lating Machine | <Volume 50L*14 tanks> |

7. Automatic Tofu Mold Stacking Machine |

|

8. Continuous Tofu Pressing Machine | <6 pressors station> |

9. Manual Mold Turn Over Machine with Cylinder | |

10. Manual Tofu Cutting Machine | <w water spray & fix cylinder> |

11. Hygiene SUS304 Tofu Mold (including top board) | <Quantity: 30 sets> |

12. Packaging (water pack or vacuum pack) | <Optional> |

13. Packaging (water pack or vacuum pack) | <Optional> |

l Process Description l

Dry Bean Washing and Soaking System | |

| |

【high & low water level detecting sensor】, to reach using low level of water for washing, high level of water on beans soaking to save water consumption. We concentrate to control the soybean soaking performance at every beginning steps. |

| Reference HMI Setting Page on Washing & Soaking System | |

| |

PLC Program Functional: |

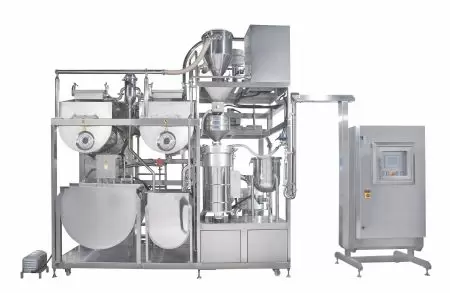

| F1502 Twin Grinding & Separating System | |

| |

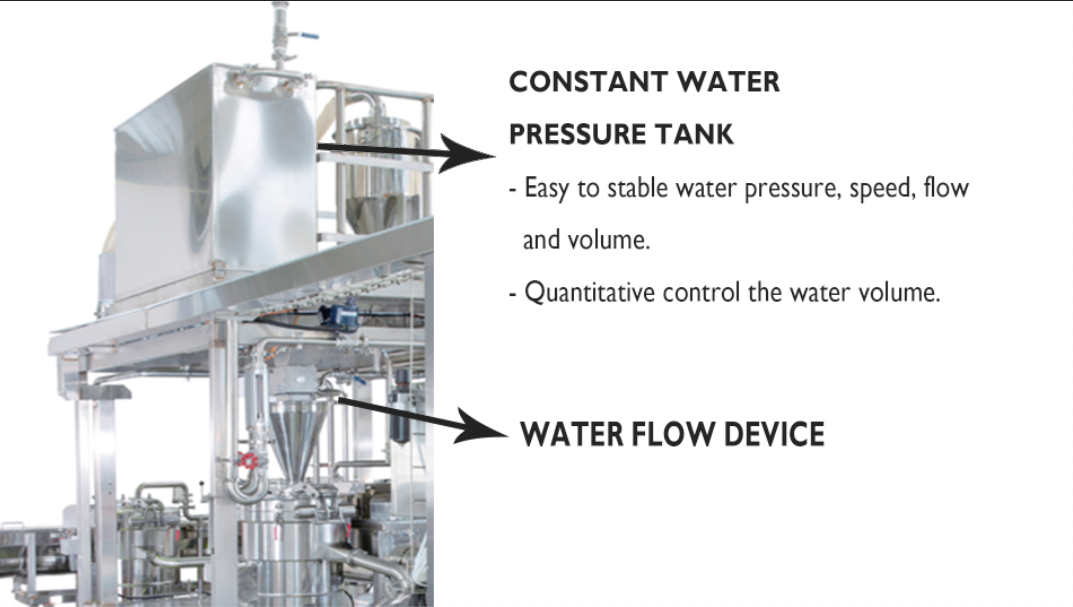

| 【Twin Grinding Design】 The F1502 system is designed with two sets of Yung Soon Lih (eversoon) Food Machine 7.5HP high-speed grinders, capable of achieving 120 kg dry bean processing per hour with safety activation. This advanced system ensures optimal soy protein extraction for high-quality soymilk production. The first grinder operates using recycled soymilk while simultaneously feeding well-soaked soybeans into the system. After the initial grinding and separating process, a soymilk slurry is collected in a buffer tank, along with Okara. The Okara is then transferred to an agitating device, where it is mixed with water for further processing. The water-mixed Okara is sent to the second grinder for double grinding and extraction, producing lightly extracted soymilk (Brix 2–3). The lightly extracted soymilk is pumped back to the first grinder, enhancing the overall soymilk yield. The second grinder is equipped with a frequency drive, increasing centrifuge speed to produce drier Okara for efficient waste management. The drier Okara from the second grinder is transported via a screw device. A high-speed blower then delivers the Okara to a designated storage container, streamlining waste collection and disposal. The double grinding process is designed to maximize soymilk extraction efficiency, ensuring minimal waste. The system includes a water pressure balance tank and an automatic bean feeding device, allowing for precise water and soybean input control to maintain consistent Brix levels in the final soymilk product. With Yung Soon Lih (eversoon) Food Machine’s advanced grinding system, businesses can achieve higher extraction rates, improved soymilk quality, and efficient waste management for a sustainable and profitable production process. |

|

| Reference HMI Production Monitor Page of Grinding & Cooking System | |

| |

| l PLC Program functional l Grinding & Separating Machine: 1. Soybean feeding speed set-able 2. Water adding volume adjustable 3. Non-soybean automatic detection 4. Automatic active or stop the grinding machine by detection of un-cooked soymilk level Cooking System: 1. Un-cooked soymilk pumping time set-able 2. Cooking temperature set-able 3. Automatic pressure detection and display Cooked Soymilk Buffer Tank: 1. Automatic cooked soymilk high, low level detection 2. Soymilk temperature set-able to active re-heating up function (insulation temperature) 3. Automatic CIP mode |

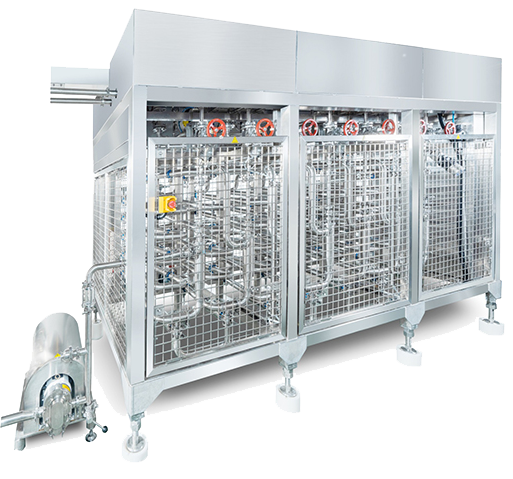

Continuous Type Cooking System (non-anti-foaming agent needed cooking system) | |

| |

To physically remove soymilk foam. No foam waste, and no need deformer agent to make your soymilk tofu health and unique. Now a days, people desire having a good health, so the consumer to purchase a food, their 1st step will be see the labeling in ingredients and nutrition facts, they don’t want to have too much food additivities in food, instead consumer desire and love a very natural ingredient, let stay our label only Yung Soon Lih (eversoon) Food Machine Tofu ingredients: |

| Cooked Soymilk Storage Tank | |

With automatic temperature detecting & insulation buffer tank help to keep cooked soymilk had best temperature, together with density stable and level control to ensure good coagulating performance of rear process. Why cooked soymilk buffer tank so important ? We insist on no use on deforming agent method to produce tofu, so soymilk after cooking, the liquid of soymilk is coming with a little bit air inside, so we need to well control the liquid level, make soymilk density stable, and soy protein stable. Then using rotary pump to pumping soymilk to destination coagulating machine doing coagulating process. We concerning about the tofu making quality, so the cooked soymilk transportation pipe is special design for temperature remaining, together with uninterrupted cooked soymilk circulation, to ensure soymilk have good coagulating temperature to get good and stable quality of tofu. |

| Automatic Tofu Coagulating Machine/Safety Defense of Coagulating Machine | |

| |

To well control critical parameters, such quantitative of soymilk volume, coagulant adding volume, curd break time, tofu water sucking time, total coagulating time to make sure your tofu high quality & stable & uniform. Traditional hand-made tofu, you will need a rich-experience worker to see and monitoring the coagulating process, to control soymilk temperature mixing with coagulant, how long should making tofu curd break? Even need to control a precise time from coagulating to fill curd into tofu mold. Too quick you will lose protein from coagulating, too long your tofu quality will become too hard, even the rick-experience of worker is out of work, you will have big problem on making tofu. Yung Soon Lih (eversoon) Food Machine automatic coagulating machine, use PLC to memorize all-important tofu production parameters to be the brain of rich-experienced worker, equipped automatic device to be the hand of rich-experienced. Yung Soon Lih (eversoon) Food Machine engineer team will also help customer to figure out best recipe of the tofu customer like, and write the setting parameters into PLC, write a hand book for customer backup. This is to help operators to reach 1 click to produce high quality of tofu, even they are no tofu production experience, just to pass some basic training then go on work. The system also separates the level of operator, management users, to avoid the operator reset the parameters without authorities. |

|

| Reference HMI (Silken Tofu) “Optional” Production Parameters Setting Page | |

| |

l PLC Program Functional l 1. Soymilk filling volume adjustable |

Applications

What is the sociability of Yung Soon Lih (eversoon) tofu making machine?

Different kinds of tofu have different texture, firmness and different meal application on your table, Yung Soon Lih (eversoon) tofu making machine is able to sociable with optional device to produce extra firm tofu, and Asian silken tofu.

I want to learn use of Extra Firm Tofu & Herb Mixed Tofu?

Extra Firm Tofu, and Herb Mixed Tofu, these 2 kinds of tofu are facing to Western people market main stream market in United States, Europe because they are firmer, the taste is quite similar to animal meat, so it is very suitable for BBQ, putting extra firm tofu small cubes on to the pizza, and also small cubes into salad.

Services

Yung Soon Lih (eversoon) Food Machine provides 24-hours online consultation, cooperates with engineers to solve customers’ problems by remote operation, saves people's round-trip time and labor cost, and solves customer problems in a timely and rapid manner.

In addition, food equipment who just started their business or expanded their factories, our senior engineers will go to the company site to survey and help you to plan the layout. In the past 36 years, We had built up a good partnership with our global customers like the Czech Republic, Poland, Canada and also transferred the technical know-how of producing soy milk and tofu to our customers. We were committed to becoming a turnkey solution provider.

- MoviesRelated ProductsFiles Download

In Tofu Production Process video clip, you can easily understand how the tofu maker machine makes the Tofu. Including the process of Soybean feeding, grinding, okara separating, raw Soy milk making, Soy milk cooking, pumping to coagulation tank, stirring, tofu pressing and filling to molds.

In Tofu Production Process video clip, you can easily understand how the tofu maker machine makes the Tofu. Including the process of Soybean feeding, grinding, okara separating, raw Soy milk making, Soy milk cooking, pumping to coagulation tank, stirring, tofu pressing and filling to molds.

120kg/hr Dry Soybean Processing: Automatic Tofu Making Machine Solution - Yung Soon Lih (eversoon) Food Machine is a state-of-the-art tofu production line. This advanced system boasts an integrated soymilk extraction unit, offering a dry bean processing capacity ranging from 100 to 120 kilograms per hour. This highly efficient tofu production line, designed in line with Yung Soon Lih (eversoon) Food Machine Company renowned coagulators, is capable of churning out 30 to 35 molds of natural standard tofu or 20 to 25 molds of firm tofu per hour, each mold weighing approximately 8.7 kilograms. | Taiwan-Based Soybean Processing Equipment Manufacturer Since 1989 | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a 120kg/hr Dry Soybean Processing: Automatic Tofu Making Machine Solution manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

We are the first food machine manufacturer whom developed the European Tofu turn-key production line, which can produce Asian Tofu, and Soy Milk processing equipment. Our tofu production machines are specially design and able to produce Tofu Burger, Vegetable Tofu, Smoked Tofu, Tofu Sausage to satisfy consumers' demand from the American and European market.